QuickHonda's Garage - Camshaft Replacement

Removal

1 Place engine in the top dead center position

2 Remove the camshaft cover and timing belt and the timing belt and camshaft sprocket.

3 Remove the distibutor. There are 3 12mm bolts around its base, once the bolts are removed the distributor will pull out of the head .

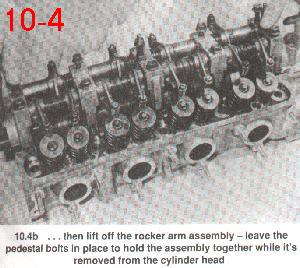

4 Loosen each rocker arm shaft pedestal bolt 1/4 turn at a time following a criss cross pattern. Once all the bolts are loose, lift the rocker arm assembly off the engine as a unit. Caution, the assembly is spring loaded and will want to expand sideways. Make sure you hold it from the ends. Invite a stupid friend over to hold this together while you're working on the cam or put a couple of nails into your workbench and place the assembly between them.

| Additional note - I have recently been told that if you leave the bolts on the outside of the assembly in place through the shafts then they will hold the whole thing together so it won't want to spring apart. |

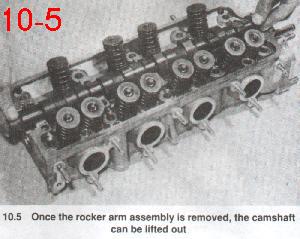

5 Lift the camshaft out of the cylinder head. Clean with a solvent and slightly spray with WD-40 to prevent oxidation. The cam lies in an oilbath, be sure not to drip any oil on the painted surfaces while removing.

Replacement

1 Lubricate the rocker arm components, camshaft lobes, journals and seal contact surfaces with engine assembly lube (camlube). Replace the camshaft oil seal.(its cheap)

2 Lay the camshaft in the cylinder head with the keyway facing up.

3 Install the rocker arm assembly and tighten the pedestal bolts finger tight.

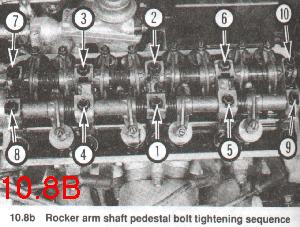

4 Tighten the pedestal bolts in 1/4 turn increments, following the sequence in illustration 10.8b, untill the specified torque is reached.

5 Install the woodruff key in the end of the camshaft and slip the timing belt sprocket into position. Tighten then sprocket bolt to the torque listed in the specs. Make sure the alignment hole is at the top and the index marks on each side are parallel to the cylinder head.

6 Reinstall the timing belt and the remaining components in the reverse order of removal.

7 If installing a new cam remember that the valves will need to be readjusted.

8 Whenever working on the valve train its always a good idea to rotate the engine 2 turns by hand while feeling for any resistance that might indicate piston to valve clearance problems.